Sustainable manufacturing

The realisation of a sustainable product starts with a sustainable production process and a circular design with smart material choices. Think of materials that we can repair or recycle well. In the search for the right components, we scrutinise their impact on the world. We calculate parameters such as CO2 emissions, material impact, impact on water and toxicity.

Our local factory

Sustainable manufacturing requires not only sustainable products, but also a sustainable production environment. Q-lite’s production runs on 100% green electricity, generated by the more than 1,500 solar panels on our roof in Baarle-Hertog.

Sustainable production can only take place in a clean factory. For this, a sound waste policy is essential. We sort some 25 raw material streams, enabling high-quality recycling of materials. These include production waste and dismantled parts of returned displays. Through short-chain cooperation with companies in the local industrial estate, there is

almost no packaging waste.

What does Q-lite understand by circular design?

A product is sustainable for Q-lite when it meets all the conditions below:

- At least 20 % of the total weight is recycled material

- Constructed from highly recyclable materials (+98 %)

- Pure electronics, plastics and foams are excluded if possible

- Waterproofing is applied to the entire cabinet rather than at the electronics level

- The product retains its appearance by using high-quality paint

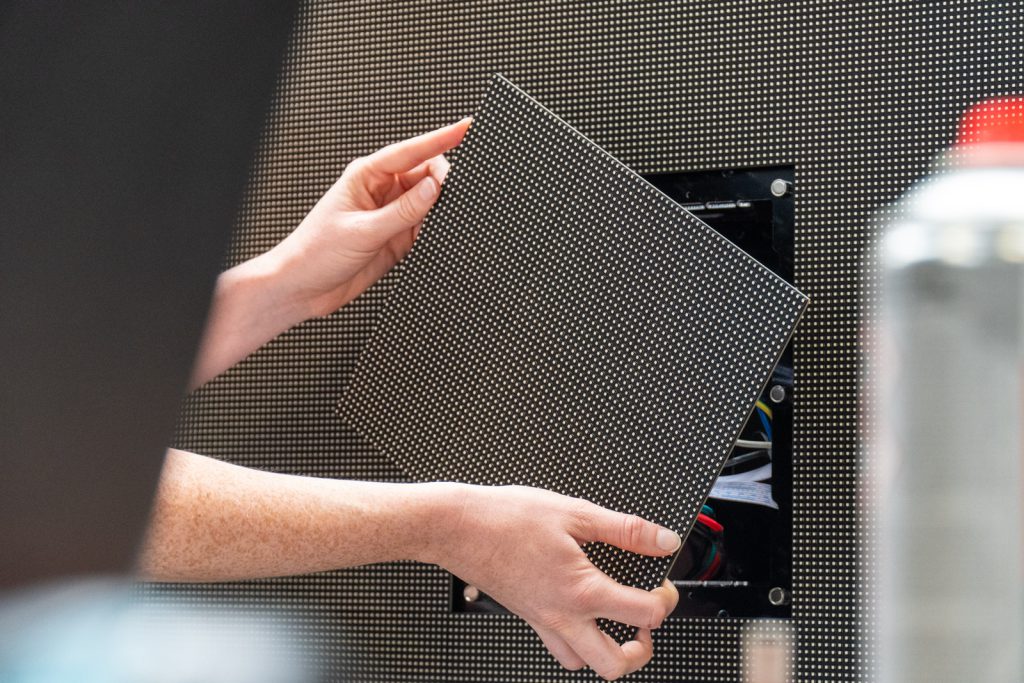

- The product is upgradeable at the pixel level and energy efficiency

- The product contains smart climate control

- The product is more energy-efficient than the market standard

- Spare parts are available for 10 years

- It has a lifespan of 10 years or more with or without upgrades

- The product is easily disassembled into clean materials for reuse or recycling

- Dismantling of the product at the end of its service life is guaranteed

Durable materials

As far as possible, we use pure materials with a low impact on the earth. Here, we look for raw materials with a low impact in the chain, which can be easily reused or recycled. Combining circular design with sustainable materials creates digital display solutions with low environmental impact.

Aluminium

Our aluminium is produced in the Netherlands, in a plant that runs entirely on its own generated green electricity. Their unique process makes it possible to obtain aluminium consisting of 80% recycled aluminium. As a result, much less energy is required during remelting than when using only primary raw materials.

Bonus: after its service life, the aluminium does become 100% recyclable and re-enters the chain. Research by VU Brussels and TU Delft shows that the carbon footprint is thus up to 20 times smaller compared to standard aluminium.

Steel

The steel we use for the supporting structures consists of 45 to 100% recycled steel. This is recovered in an electric arc furnace (EAF).

- With 100% recycled steel, only lime and oxygen are added to bind any impurities.

- In the case of galvanised steel, the zinc is recovered and reused in the production of new zinc.

Fasteners

Due to the unique modular design, many nuts and bolts, or fastners, are required. For this, we use European-made steel ones, which consist of 45% recycled steel.

Glass

For various display solutions, we place a glass plate in front of the LEDs for protection. This 100% recyclable glass is produced in the Benelux.

Concrete

Q-lite uses sustainable SQAPE concrete. With concrete, 95% of the CO2 impact is in the binder, or cement. Here, this is replaced by a patented, unique binder, which allows the concrete to be recycled in the normal recycling circuit and thus has +-80% less CO2 impact compared to standard concrete with Portland cement.

Packaging

We reuse packaging materials we receive ourselves, such as air bags and bubble wrap, as often as possible. What we can no longer use ourselves is collected by a local e-commerce company, giving the materials get a second life. When we install a display ourselves, we take the protective films and packaging back to be reused internally.

Through recycling and clear guidelines for our suppliers, our residual waste has been reduced by more than 50% since 2018, despite our strong growth. As much recyclate as possible is incorporated into tapes, films and recycled testliner board.